ABOUT US

MAREMOD SA is a 100% privately owned company that was founded in 1997. The company is recognized as one of the most important clothing manufacturers in Romania with a large production capacity, distinguished by its high flexibility, qualified staff with a vast experience gained in collaboration with external partners and in the execution of premium quality garments.

The main object of activity is the production of men’s and women’s trousers, classic and casual in proportion of 95% export and 5% domestic market, under its own brand “La Viggio”. Since 2015, Maremod has diversified its activity in the field of knitwear, developing a factory modernly equipped with state-of-the-art knitting and finishing machines, which produces fully knitted products.

In the conditions of the COVID-19 pandemic, there was an urgent need for medical devices and personal protective equipment both to meet the growing requirements of the public health system for such products and to apply social distance measures to the population , in order to prevent the spread and control of the virus.

Thus, in this context, in the spring of 2020, proving with flexibility and inventiveness, Maremod S.A. purchased an automatic surgical mask product line and set up a department to make protective suits (robes and hooded jumpsuits), thus joining the fight to remove, limit and stop the spread of viruses, such as the new coronavirus, scientifically called SARS-CoV -2 and the avoidance of illness with Covid 19. Thus Maremod SA also became a manufacturer of high quality medical devices, these being registered with ANMDMR.

The factory is located in a large, modern industrial building and is equipped with high-performance equipment, including automatic equipment. Thanks to the latest generation equipment, Maremod ensures a high quality standard for all products made on its manufacturing lines as well as medical devices.

Short history:

1996 – construction of the factory building

1997 – focusing on pants production

2000 – capacity expansion for long and short pants (600 employees)

2005 – introduction of blazers; improving productivity (425 employees)

2016 – massive investments are made in state-of-the-art knitting machines through EU research grants; introduction of knitting products (140 employees)

2017 – another investment financed with EU funds for the purchase of state-of-the-art cars, including automatic cars.

2020 – expanding the field of activity against the background of the pandemic, by organizing lines for the production of medical devices: protective coveralls with hood and disposable gowns, along with the purchase of an automatic product line for disposable facial masks.

BRANDS AND PRODUCTS

Maremod S.A. is also the owner, manufacturer and distributor of the brand “La Viggio” in Romania. Taking into account the quantitative structure of production in recent years and the variation of the market, MAREMOD S.A. focused its production on the following products:

- Long pants (men and women)

- Shorts (men)

- Knitwear (men and women)

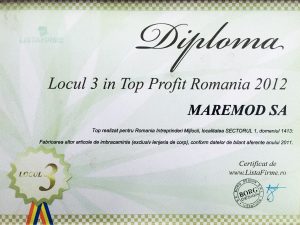

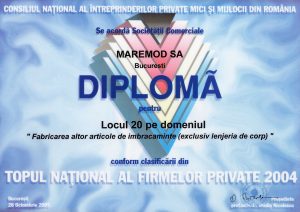

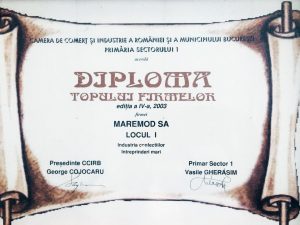

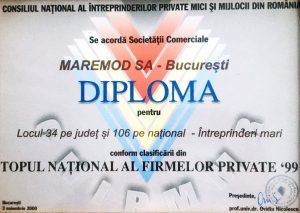

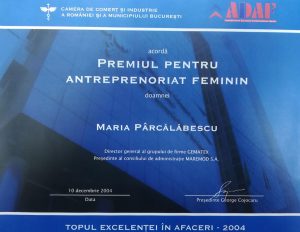

AWARDS & DIPLOMAS

AFFILIATIONS